WHY US?

New generation intelligent adiabatic system with total condenser protection

No condenser corrosion

Four-step water treatment means no mineral deposit on condenser

No Legionella

Vast experience

Over 15 years’ experience in desiccant dehumidification.

Made in Europe

All components made exclusively by European manufacturers.

EU standards

Equipment compliant to all applicable EU directives and regulations.

Our technology

A closed-loop high pressure adiabatic pre-conditioning and control system designed to extend the stable operating envelope of air-cooled chillers by managing condenser air inlet conditions. Intelligent adiabatic Smart Cooling™ system combines an adiabatic evaporative pre-cooling process and condenser protection with mechanical air filtration. The intelligent adiabatic Smart Cooling™ system is mounted externally in front of the condensers of the cooling equipment. Read More

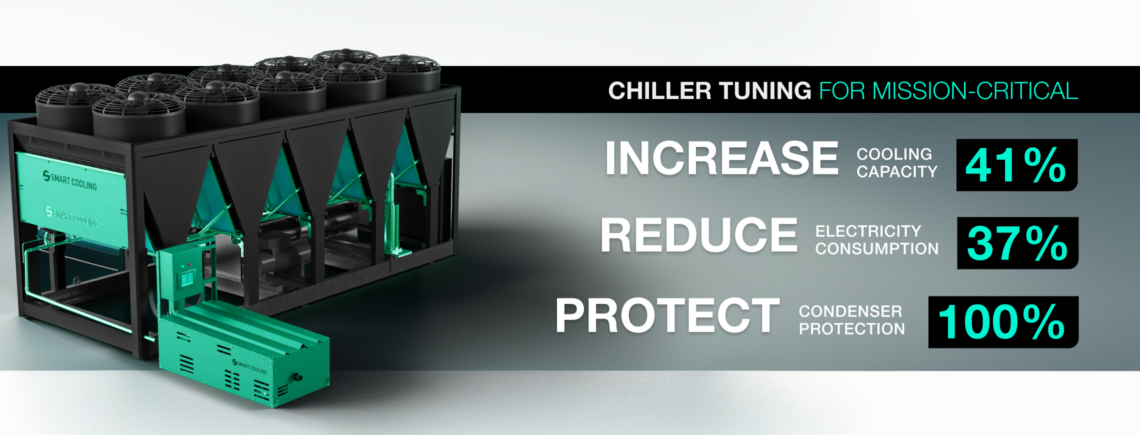

Smart Cooling™️ for Mission Critical

To meet the highest reliability standards in mission-critical environments, we have developed a universal Smart Cooling™️ KIT designed for all air-cooled chiller types.Our system integrates seamlessly with any manufacturer’s units and ensures stable, efficient condenser temperature control under the most demanding operating conditions.The Smart Cooling™️ solution is compatible with all major chiller brands, including York, Carrier, Trane, Daikin, and many others.Read More

Product & Components

The new generation intelligent adiabatic chiller booster Smart Cooling™ system combines state-of-the-art materials with cutting-edge technology. Chiller booster Smart Cooling™ is standardized and can be customized for any cooling equipment type. Read More

Stable Chiller Operation During Peak Ambient Conditions

Smart Cooling stabilizes condenser operation during peak ambient conditions, when conventional chiller control reaches its operational limits, while maintaining controlled water consumption.

Read More

Mission Critical 1 – Technology Video

Controlled, Non-Disruptive Integration

To ensure a controlled and repeatable installation process, Smart Cooling systems are designed as standardized, OEM-compatible modules that integrate without modifying existing chiller infrastructure. Read More

Mission Critical 2 – Technology Video

Discover the real-world results of the new generation intelligent adiabatic pre-cooling Smart Cooling™ system. Several of the world’s largest companies save energy and boost cooling unit efficiency. Learn more about energy monitoring and efficiency results as well as our exulting customer reviews. Read More

On May 21, 2020, SIA “Blue Energy Global” reg. No.40103825584 has entered into an agreement No. SKV-L-2020/31 with the Investment and Development Agency of Latvia on receiving support within the measure “Promotion of International Competitiveness” co-financed by ERAF.