System Architecture-Controlled Air Pre-Conditioning with Condenser Surface Isolation

The intelligent adiabatic Smart Cooling™️ system combines adiabatic evaporative air pre-cooling with full condenser protection and mechanical air filtration. The system is installed externally, upstream of the condenser air intake, forming a continuous protective interface between the ambient environment and the cooling equipment.

The Smart Cooling™️ system provides total (100%) physical protection of the condenser surface, preventing direct water contact with condenser fins and heat-exchange surfaces. This protection concept has been proven through testing and operational deployment, ensuring safe, controlled operation without introducing moisture-related risks to the condenser.

The intelligent control logic initiates the adiabatic process prior to the activation of mechanical cooling, allowing the equipment to receive temperature-reduced intake air through a fine, controlled mist of processed water, fully isolated from the condenser surfaces.

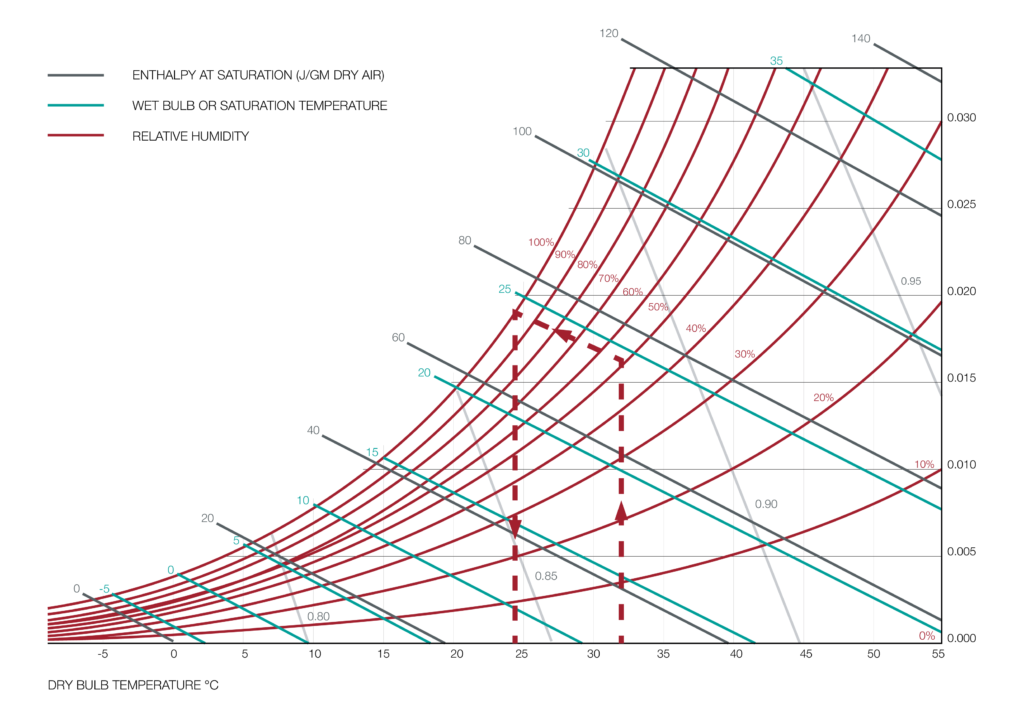

During operation, the inlet air temperature entering the condenser is reduced, typically within the range of 10 °C (50 °F) to 20 °C (68 °F), depending on ambient conditions. This reduction lowers the condensing temperature within the refrigeration circuit, resulting in improved chiller operating efficiency, with measured efficiency improvements of up to 37% under suitable climatic conditions.

The system design supports reliable, repeatable, and safe operation, making it suitable for mission-critical cooling applications in alignment with ASHRAE best practices and high-availability data-center requirements.

New generation intelligent adiabatic chiller boosting system with total condenser protection

Watch videos

New generation intelligent adiabatic chiller boosting system with total condenser protection

Video – Smart Cooling™ system explainer Adiabatic cooling chiller booster Smart Cooling PRO10

Condensers must be protected from corrosion, mineral deposit (limescale) and other harmful elements. Smart Cooling™ uses a patented protective membrane (pre-filter) that safeguards condensers against calcium and mineral deposits, corrosion, dust and sun rays. The membrane prevents water mist from coming into direct contact with the condenser. The self-cleaning membrane captures water mist, direct sunlight and dirt. The membrane’s special cell material does not create additional resistance to airflow into the condenser.

The intelligent adiabatic pre-cooling system concept behind Smart Cooling™ is based on adiabatic evaporative cooling: the delicate process of spraying treated water using a fine water mist to cool intake air flowing into the condensers in advance without damaging or incurring efficiency loss on the condensers.

Water purification also plays a significant role, therefore Smart Cooling™ has a four-step water treatment module to safeguard condensers from dust, calcium and mineral deposits (limescale), algae and bacteria (including Legionella).

The pressure in the adiabatic system ranges from 70 to 140 bar (PSI 1015,26 – 2030.53) and provides highly effective water spraying and evaporation, hence a significant reduction of temperature from dry to wet bulb.

The new generation intelligent PRO 1 Controller and its dedicated software provide the brainpower to the Smart Cooling™ system, ensuring that the operation of the adiabatic system is maximized while maintaining minimal water consumption. The controller analyzes air temperature, air humidity, chiller load and its daily cycle. Based on these finely measured parameters, the PRO 1 automatically alternates operating modes resulting in 100% water evaporation and maximum efficiency.

The temperature of incoming air flowing into the adiabatic Smart Cooling™ system substantially decreases during the adiabatic process, at levels registered between 10°C (50°F) to 20°C (68°F).

The lower air temperature produced by the Smart Cooling™ system dramatically increases the cooling capacity of the cooling unit. By allowing the unit to operate with a significantly lower temperature from the very beginning, less electricity is used and tremendous gains in efficiency and cost-reduction are achieved.

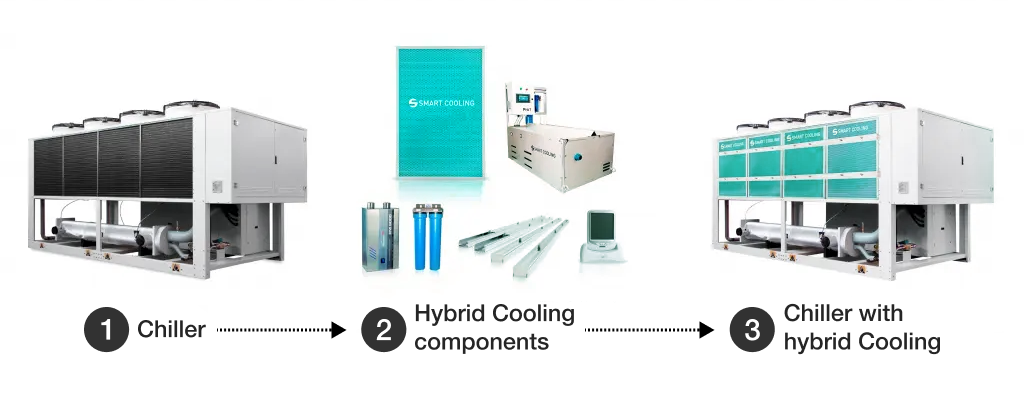

Our system is modular and applicable to all types of dry coolers and chillers. All system components are designed so that the Smart Cooling™ system can be installed quickly, easily and with the greatest reliability and longevity in the market.

Find here further information on Smart Cooling™ components.

Note:

The intelligent adiabatic Smart Cooling™ system does not adversely affect the way the air conditioning or cooling systems work nor the nature of its operation as intended by the manufacturer.

Smart Cooling™ reduces the air temperature flowing into the unit, enabling the air-cooling unit to function in regular modes instead of higher settings otherwise necessary for operations in conditions of strong heat.

An illustration of the installed Smart Cooling™ system is shown below.

Features of the Smart cooling™ system:

- Membranes

The membrane (pre-filter) protects the condenser from calcium and mineral (limescale) deposits. The membrane prevents the water mist from coming into direct contact with the condenser. The self-cleaning membrane captures water mist, direct sunlight and dirt. The membrane’s special cell material does not create additional resistance to airflow into the condenser.

- Nozzle panel

The micro nozzles create a mist wall sprayed in front of the condenser. When water comes into contact with hot air it evaporates instantly. This provides substantial savings in water consumption.

- No calcium carbonate risk

Water is treated with uniquely developed biochemicals before entering the intelligent adiabatic evaporative Smart Cooling™ pre-cooling system, changing the structure of calcium carbonate molecules and preventing them from adhering to surfaces and depositing as harmful limescale.

The biochemical substance and process 100% environmentally friendly.

- No Legionella

Smart Cooling™ is equipped with ultraviolet sterilizers that eliminate all bacteria in the water passing through the system, including Legionella.

- Total condenser protection

Protecting the condensers from deposits, dirt and direct sunlight is essential for your cooling system. Smart Cooling™ protective membranes safeguard your condensers with great efficacy. The cleaner the condenser of your cooling equipment the better heat exchange and removal processes take place. Smart Cooling™ protective membranes ensure greater longevity and higher efficiency, while the adiabatic panels guarantee air pre-cooling and prevent your equipment from overheating.

- Compatible with all conditioning and cooling units

Smart Cooling™ fits all air conditioning and cooling units of any capacity. Due to its unique modular assembly, the installation of the adiabatic pre-cooling system Smart Cooling™ is done in a single day.

If your cooling unit is experiencing or is predicted to experience loss in cooling capacity, Smart Cooling™ is the solution you can get now!

- Minimum maintenance

Maintenance is easy and economical. All you have to do is to replace the BIO Tablets once a month. A process that takes less than five minutes and can be done by your maintenance staff or any trained staff member.

- Monitoring system

The adiabatic pre-cooling system Smart Cooling™ is equipped with a monitoring system that measures electrical consumption, allowing you to observe the gains in electrical consumption savings after the installation of Smart Cooling™.

The principle of adiabatic evaporative cooling process is illustrated in the ID diagram below:

We invite you to witness the effectiveness of our technology:

- Read reviews and case studies from existing Smart Cooling™ customers or contact us directly to learn more.

- Familiarize yourself with our products with our explainer video.

- See the technical illustrations and data proving the dramatic air temperature decrease that can be achieved by Smart Cooling™.

- See how Facebook uses this technology in its data center.