Adiabatic Cooling System Components

| 1 . BY 70 SS – Nozzle Panel |

Component Description

The BY-70 SS nozzle panel assembly is manufactured from high-grade stainless steel 316 L and aluminum alloy materials, suitable for continuous outdoor operation and long-term use in air-cooled heat rejection systems serving mission-critical facilities.

The stainless-steel 316 L nozzle distribution routing shall be fully integrated within a high-strength anodized aluminum enclosure, providing mechanical protection and corrosion resistance for the fine-spray water release components. The enclosure design shall ensure durability under vibration, thermal cycling, and environmental exposure.

The nozzle panel casing shall be engineered for rapid installation and simplified maintenance, allowing access to nozzle components without removal of adjacent equipment and without interruption to redundant cooling paths.

Nozzle assemblies is secured to the enclosure using dedicated mechanical fastening elements, providing secure, vibration-resistant attachment compatible with a wide range of air-cooled condenser and chiller configurations. The mounting solution ensure reliable fixing without imposing structural stress on the air-cooled equipment.

The assembly is suitable for use in adiabatic or evaporative air pre-cooling applications, supporting improved heat rejection efficiency while maintaining high availability, maintainability, and operational resilience, in alignment with ASHRAE design practices and mission-critical data center reliability principles.

| Read More >> |

| 2 . BY 70 M – Reflective Membrane |

No water contact with condenser fins

No water contact with condenser fins or heat exchange surfaces.

The BY-70M reflective membrane system is designed to fully isolate the air-cooled condenser from direct water exposure, eliminating risks associated with corrosion, fouling, coil degradation, and unplanned maintenance.

The membrane assembly is constructed from multi-layer aluminum and a polyurethane alloy cellular structure, mounted in a mechanically rigid anodized aluminum housing. The system provides 100% coverage of the condenser air-intake surface, ensuring consistent protection across all operating conditions.

The solution introduces an air-side pressure drop limited to 25 Pa, maintaining compliance with standard chiller fan design margins and without compromising airflow redundancy, fan performance, or system availability.

The design supports high availability and maintainability objectives, aligning with Uptime Institute principles by:

- Avoiding moisture-related failure modes

- Preserving long-term condenser performance

- Reducing operational risk and maintenance intervention

- Supporting continuous operation in mission-critical environments

Smart Cooling™️ technology enhances air-cooled chiller efficiency while maintaining the reliability, predictability, and resilience required for Tier-certifiable data center infrastructure.

| Read More >> |

| 3 . BY 70 – UV chiller booster unit PRO 10 |

Product description (factual)

The PRO-10 high-pressure chiller booster provides a regulated operating pressure range of 70–140 bar ( 1,015–2,031 psi) within the adiabatic air pre-conditioning system serving air-cooled chillers.

The pumping station integrates a purpose-designed high-pressure pump, control valves, and electronic control components within a self-contained assembly, enabling fully automated operation of the adiabatic pre-cooling system.

An integrated ultraviolet (UV) water treatment module is installed within the booster unit. The module utilizes a nested arrangement of UV lamps to continuously treat process water, providing microbiological control and water hygiene protection. The UV system reduces bacterial contamination, including protection against waterborne pathogens such as Legionella, without the use of chemical additives.

A 100% water recirculation module is included, enabling closed-loop water management and minimizing water consumption. The recirculation system incorporates:

- An electromagnetic water treatment system to limit mineral scaling and biofouling

- A five-stage water filtration process for particulate and contaminant removal

- Overflow protection to prevent uncontrolled water discharge

- Integrated controllers and sensors for continuous system monitoring, control, and operational safety

The combined system supports stable operation, water quality control, and long-term reliability, making the PRO-10 booster suitable for adiabatic cooling applications in data centers and other high-availability facilities, in alignment with ASHRAE best practices and mission-critical reliability principles.

| Read More >> |

| 4 . BY Water treatment system |

Water treatment system – factual description

The system includes a four-stage water treatment process designed to manage water quality and reduce the presence of limescale, microbiological contaminants, airborne dust, and other undesirable particulates within the adiabatic cooling circuit.

Stage 1 – Pre-filtration

Process water is filtered to remove dirt, suspended solids, and particulate contaminants prior to circulation within the system.

Stage 2 – Electromagnetic water treatment

An integrated electromagnetic water treatment device modifies the crystallization behavior of dissolved calcium and magnesium compounds, reducing the tendency for limescale deposition on metallic and heat-transfer surfaces.

This process supports scale mitigation without chemical additives and contributes to the protection of air-cooling equipment components.

Stage 3 – Corrosion protection support

The electromagnetic treatment process assists in reducing mineral adhesion and corrosion risk, supporting long-term protection of metallic components against rust formation under continuous operating conditions.

Stage 4 – Ultraviolet (UV) disinfection

The treated water is exposed to ultraviolet (UV) radiation to limit microbiological growth, including mitigation of waterborne bacteria such as Legionella, enhancing water hygiene within the recirculating system.

The four-stage treatment process supports stable water quality, reduced maintenance requirements, and long-term reliability, making it suitable for mission-critical adiabatic cooling applications in accordance with ASHRAE best practices and data-center reliability principles.

| Read More >> |

| 5 . PRO 1 – Control Panel |

PRO-1 control panel – factual description

The PRO-1 Control Panel autonomously initiates and regulates operation of the intelligent adiabatic cooling system based on predefined temperature thresholds and operating logic.

The control panel manages system operational sequences, including start-up, modulation, and shutdown, ensuring coordinated interaction between system components. The enclosure is manufactured from high-quality PE materials, providing durability and suitability for continuous operation in HVAC equipment environments.

The PRO-1 Control Panel supports integration with HVAC Building Management Systems (BMS), enabling centralized monitoring, control, and operational visibility.

The controller continuously analyzes ambient air conditions and chiller operating status, adjusting system operation to deliver precisely regulated water flow in accordance with real-time demand. This control strategy supports efficient water usage, stable thermal performance, and reliable system operation.

The PRO-1 Control Panel is suitable for use in all pre-cooling applications, aligning with ASHRAE and TIER control and reliability principles for air-cooled chiller systems.

| Read More >> |

| 6 . BY – Fittings |

Component Description

The connective elements and fastening components used throughout the Smart Cooling™️ adiabatic cooling system are manufactured from corrosion-resistant materials, including stainless steel AISI 316L and brass.

These materials provide high mechanical strength, corrosion resistance, and long-term reliability, making them suitable for continuous outdoor operation and exposure to water, humidity, and environmental contaminants commonly present in air-cooled HVAC installations.

The fastening and connection design supports precise alignment and secure assembly of all Smart Cooling™️ system components while maintaining structural integrity under vibration and thermal cycling.

The modular construction of the Smart Cooling™️ adiabatic cooling system allows rapid assembly and disassembly, enabling seasonal removal, inspection, or maintenance, including system deactivation or dismounting during winter operating periods.

All connective elements and fastening components have been tested for corrosion resistance under salt spray conditions for up to 4,000 hours, demonstrating suitability for harsh environmental.

| Read More >> |

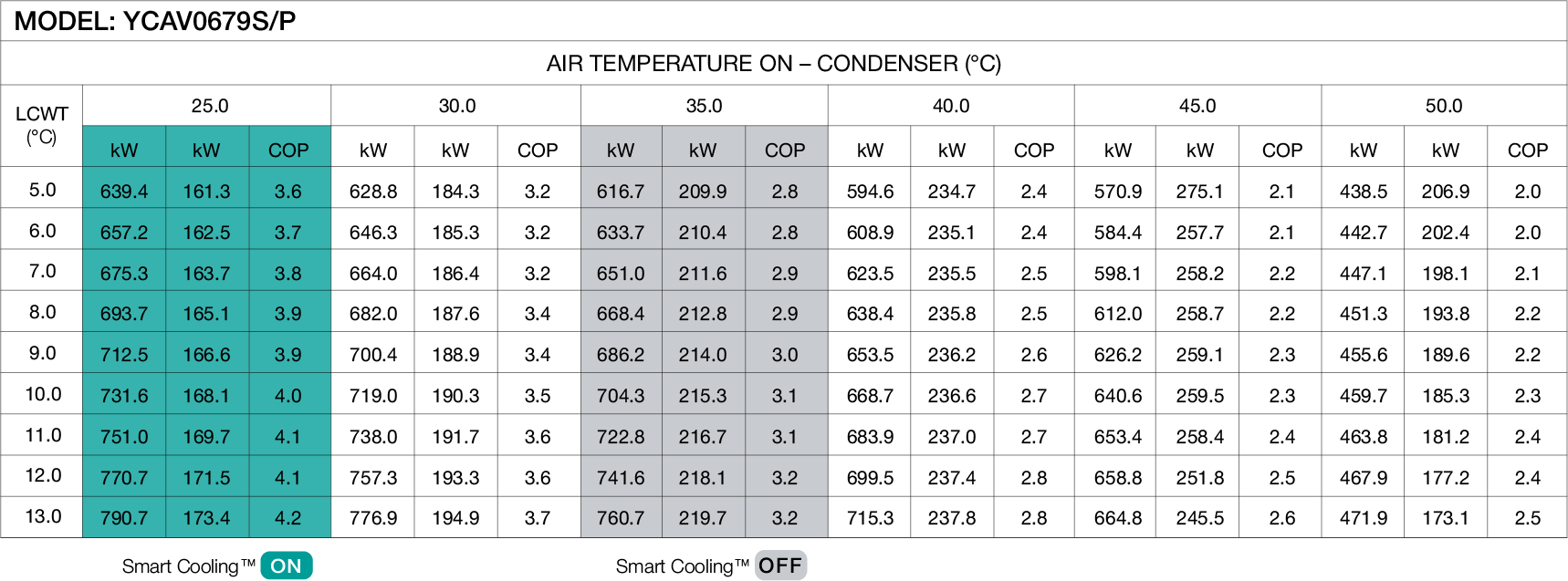

The proven results of how the chiller booster Smart Cooling™ system increases chiller efficiency are visible from data provided by chiller manufacturers. Information on chiller performance, cooling capacity, energy consumption and chiller COP is available in the form of standardized tables. These tables show the cooling capacity a unit can provide under certain ambient air temperatures, along with how much power is used in kW/h

What data show is that regardless of the manufacturer, the higher the air temperature entering the chiller system, the greater the required cooling capacity and consequently, the higher the electrical consumption is.

Discover below how the cooling capacity and electrical consumption in hot weather visibly change when the cooling unit is being benefitted by the adiabatic chiller booster Smart Cooling™ system. The unit in this case is a York chiller with screw compressors.

NOTES:

- T = 25°C (77°F) / T = 35°C (95°F)

- kWo = Unit kW Cooling Capacity Output

- kWi = Compressor kW Input

- COP = Coefficient of Performance (includes condenser fan power)

- LCWT = Leaving Chilled Water Temperature

- Ratings based on 0.15 L/s coоler water per ton and 0.018 (m2 – °C ) / kW

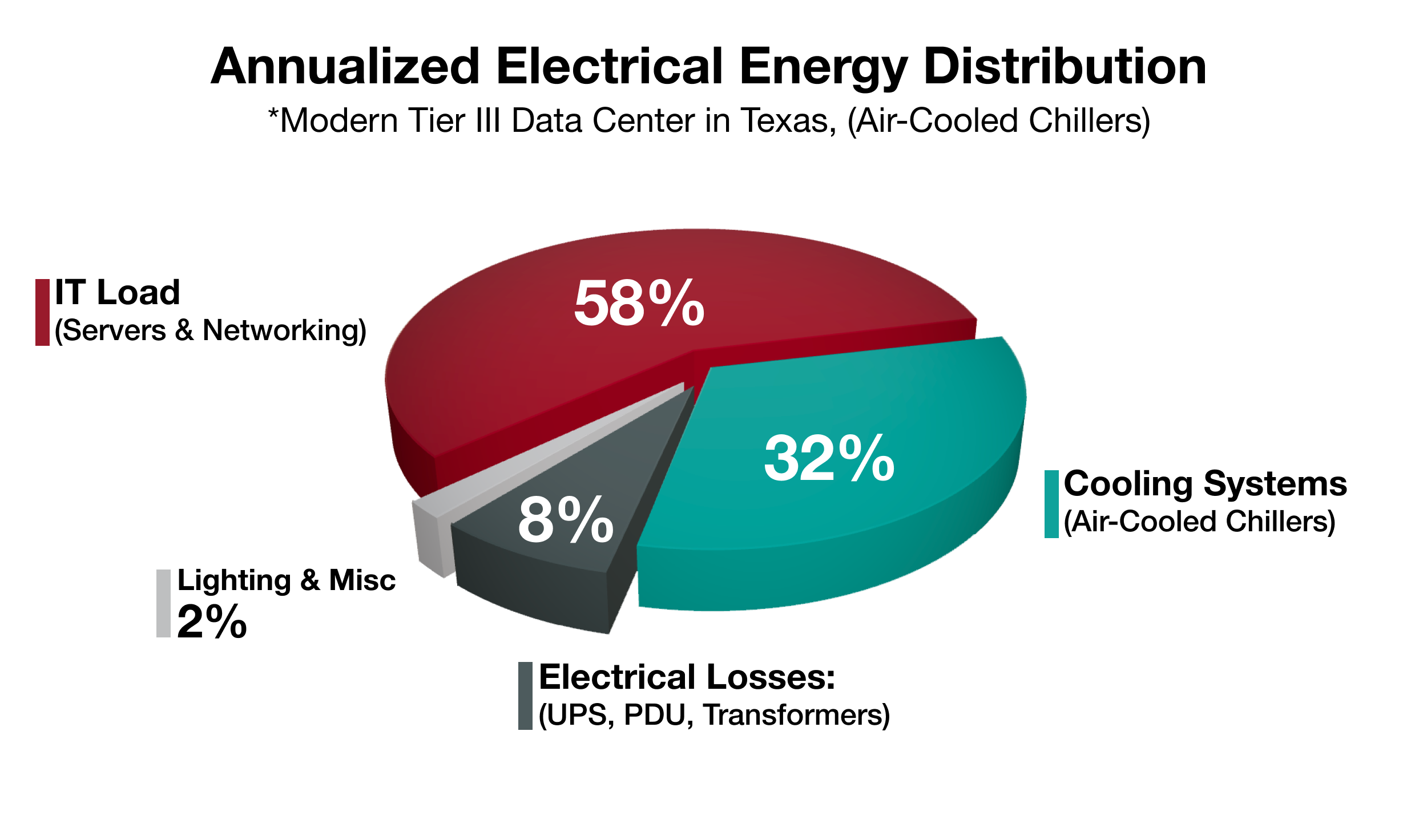

Electric Energy Consumption Distribution

Mission-Critical Data Center – Air-Cooled Chillers | Texas Climate

In mission-critical data centers located in hot climate regions such as Texas, ambient air temperature is a primary factor influencing air-cooled chiller performance and overall facility energy consumption.

Ambient Temperature Context – Texas

Typical summer design conditions for major Texas locations range between:

- ASHRAE 1% design dry-bulb temperature:

38–41°C (100–106°F) - Typical peak operating range:

35–43°C

Under these conditions, air-cooled condensers operate near their thermal limits for extended periods, resulting in elevated condenser pressure and increased compressor power demand.

Impact of Ambient Temperature on Chiller Performance

For air-cooled chillers, compressor power consumption is strongly correlated with condenser temperature and pressure. This relationship can be simplified as:

COP = Qcooling / Wcompressor

Where an increase in condenser temperature leads to:

- higher discharge pressure

- increased compressor lift

- higher electrical power input

A simplified engineering relationship often used in preliminary analysis:

ΔW ≈ k · ΔTcond

Where:

- ΔW = change in compressor power

- ΔTcond = change in condenser saturation temperature

- k = system-dependent coefficient

In practical terms, a reduction of condenser inlet air temperature by 1–2°C can result in a compressor power reduction of approximately 2–4%, depending on chiller type and operating conditions.

Role of Adiabatic Pre-Cooling

Smart Cooling™️ adiabatic pre-cooling technology reduces the effective condenser inlet air temperature during high ambient conditions by leveraging controlled adiabatic evaporation.

The theoretical temperature reduction potential is defined by:

Tout = Tdb − η · (Tdb − Twb)

Where:

- Tout = air temperature entering the condenser

- Tdb = ambient dry-bulb temperature

- Twb = ambient wet-bulb temperature

- η = adiabatic effectiveness (typically 0.6–0.85)

In Texas summer conditions, where:

- Tdb ≈ 40°C

- Twb ≈ 23–26°C

this enables a practical condenser inlet air temperature reduction of 6–10°C during peak hours, directly improving heat rejection efficiency and reducing compressor electrical load.

Energy Distribution and Engineering Significance

As illustrated in the energy distribution chart, cooling systems typically account for approximately 40–50% of total facility electrical energy consumption in air-cooled data centers operating in hot climates.

Given this distribution, targeted efficiency improvements within the cooling system—specifically at the condenser level—offer the highest leverage for energy reduction without compromising redundancy, availability, or operational reliability.

ASHRAE Alignment and Standards Reference

This analysis and system approach align with established ASHRAE guidance, including:

- ASHRAE Handbook – HVAC Systems and Equipment

(Air-Cooled Chiller Performance Characteristics) - ASHRAE Handbook – Fundamentals

(Heat rejection, psychrometrics, and evaporative cooling principles) - ASHRAE TC 9.9 – Mission Critical Facilities, Data Centers

(Thermal guidelines and efficiency considerations)

The Smart Cooling™️ system operates within ASHRAE-recommended environmental envelopes and does not alter IT inlet air conditions or violate allowable temperature or humidity limits.

Recommended Engineering Footnote

Performance impact depends on ambient conditions, chiller design, load profile, and system configuration. Energy distribution and temperature values shown are representative of typical mission-critical air-cooled data center installations in Texas climates.

JOHNSON COMTROLS

We have analyzed the cooling capacity and energy consumption data of the chiller at ambient air temperatures of 25°C (77°F) and 35°C (95°F). The latter is shown at the table in red color. Following the data from the table we get the following indicators of cooling capacity and power consumption:

T = 25°C (77°F), N (cooling capacity) = 675,3 kW/h; N (electricity) = 163,7 kW/h

T = 35°C (95°F), N (cooling power) = 651 kW/h; N (electricity) = 211,5 kW/h

By using the adiabatic Smart Cooling™ system the temperature of incoming air was reduced to 25°C. Based on the manufacturer’s data performance sheet show in the table, the following parameters were obtained: Saving power consumption of 47,6 kW/h (around 21%) based on the calculation N (T, 25°C (77°F) – T, 35°C(95°F)) and % N (T, 35°C(95°F) – T, 25°C (77°F)). COP increasing from 2,9 to 3,8 (about 34%) based on the calculation N (T, 25°C (77°F) – T, 35°C(95°F)).

The installation of the Smart Cooling™ system is a solution to problems of low cooling capacity and high electrical consumption. Smart Cooling™ results are clear evidence of the success of the system in increasing cooling capacity and reducing electrical consumption, as this example demonstrates. You can find detailed test results here

Please contact our technical experts today to unveil the savings you will achieve by installing the Smart Cooling™ adiabatic system onto your existing air conditioning and cooling system. For more tests, please click here

How do I know this product is suitable for me?

We provide the all-important answers to some of the most frequently asked questions when investing in Smart Cooling™ technology.

- Is the intelligent adiabatic pre-cooling Smart Cooling™ system endorsed by air conditioning and cooling unit manufacturers?

The Smart Cooling™ system is recognized by leading manufacturers and service companies in the air-cooling industry. Smart Cooling™ technology increases the efficiency of air conditioning and cooling units by lowering the temperature of inlet air. As the Smart Cooling™ system reduces air temperature before it enters the condensers of the air conditioning or cooling unit, technical processes remain unaffected.

- How do you ensure the Smart Cooling™ system will generate the expected results?

The Smart Cooling™ system begins its work even before the air reaches the condenser components of the air conditioning and cooling unit. The temperature of the air passing through the system is reduced by our smart release technology, which creates a fine mist that cools the surrounding air as it evaporates.

This adiabatic process significantly reduces the temperature of the air entering the air conditioning or cooling unit. As a result, the unit uses much less power to cool the air into the desired temperature in hot climates or heat seasons.

Further details on how savings are calculated can be found here.

Further information on the adiabatic process principles can be found here.

- Where can I read reviews of customers using the intelligent pre-cooling Smart Cooling™ system?

You can discover how our clients have benefitted from Smart Cooling™ adiabatic solutions here.

You can read our customers case studies here.

- What additional operational costs are incurred when using Smart Cooling™ system?

While using the intelligent pre-cooling system cooling system, the following costs are incurred:

- While using the intelligent adiabatic pre-cooling Smart Cooling™ system the following costs are incurred:

Exclusive BIO Tablets are added to the water to eliminate limescale forming on the condenser of air conditioners or cooling units. The BIO Tablets should be replaced once a month, in a quick and easy process that takes less than 5 minutes and can be done by our usual maintenance provider or trained staff member.

The BIO Tablets actively alter the molecular structure of the water to neutralize lime molecules and prevent limescale build-up and corrosion on the surface of the cooling unit. They also work along Smart Cooling™ system’s UV lamps to eliminate harmful bacteria, including Legionella.

2. Water consumption for Smart Cooling™ smart-release fine mist micro-nozzle components uses, on average, up to 4-6 m³ of water per day.

- How long is the warranty coverage?

The adiabatic Smart Cooling™ system comes with a comprehensive 2-Year warranty.